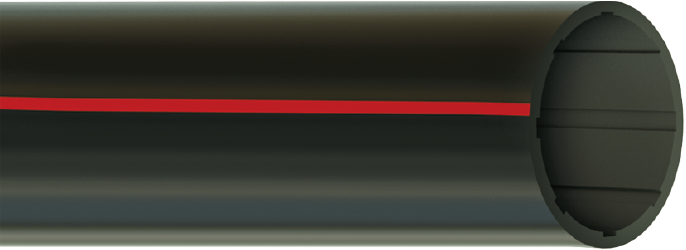

Communications Conduit

Power Conduit

Overhead power lines are susceptible to storm damage and require continuous maintenance from “tree topping” to pole maintenance and replacement. Underground power lines, protected by HDPE conduit, are gaining popularity with utilities. Furthermore, underground power lines improve curb appeal and make neighborhoods more aesthetically pleasing. Power cable systems are designed for long life, the use of HDPE conduit to encase and protect the power cable from rock impingement is prudent engineering as it allows for quick and easy repairs without excavation of the cable. HDPE conduit and innerduct is used to carry low (600V-transformer to end user) and medium ( < 35kV-substation to transformer) voltage power lines.

HDPE Conduit Benefits and Options

Blue Diamond offers a wide range of products in sizes 1/2" through 6" in a variety of colors and striping combinations. Other options include pre-lubrication, pre-installed pull tape, pre-installed cable in conduit and a toneable wire. Blue Diamond complies with RUS/USDA standards, meets Buy America Requirements and all national specifications including ASTM, NEMA and UL.

HDPE conduit benefits include:

- A wide temperature range for installation, from -20 degrees C to 90 degree C operating temperature for cables

- A low coefficient of friction (20% lower than PVC) to allow for long cable pulls

- Tough, durable and a life expectancy well over that of the power cable.

- Replace or repair cable lines without digging or trenching

- Chemical and corrosion resistance

- Easy installation, HDPE pipe is the preferred material for HDD (Horizontal Directional Drilling), because of its long continuous lengths and high pull strength

- HDD benefits include the elimination of traffic disruption and minimal surface damage

- Can be continuously plowed as opposed to trenching PVC sticks.

Smooth Wall Conduit

Smooth wall is the industry standard High Density Polyethylene (HDPE) Duct. The interior of smooth wall has a slick finish which delivers a low coefficient of friction for easy blowing or pulling of cable. It can also be pre-lubricated in our manufacturing facility for an even lower coefficient of friction. Smooth wall innerduct is a durable high quality product for direct burial and HDD (horizontal directional drilling) applications. Smooth wall is also used as an “innerduct”, meaning several conduits are placed inside a larger casing pipe.

Ribbed Wall Conduit

Blue Diamond’s ribbed wall innerduct conduit is designed to allow extremely long cable pulls to glide over the interior raised ribs. Ribbed wall innerduct is internally ribbed and available through 3” diameter in any SDR and SIDR ratings.

Specialty Conduit

Blue Diamond has the capabilities to manufacture a variety of HDPE conduit for specialty applications. BDI tracer wire (or toneable) conduit provides a method of locating underground fiber optic cable using a single copper wire co-extruded onto the wall of the conduit. This provides a traceable corrosion resistant conductor. An alternative method of locating buried fiber optic cable is to use traceable pull tape, available pre-installed in any of our duct products.

Blue Diamond has a variety of options for color and identification of your HDPE. The standard color for telecommunications applications is orange. Typical color for power applications is black with red stripes or red.

*Special colors may also be available.

**Yellow is not recommended as it is the color of gas distribution piping.

In addition to solid colors, Blue Diamond offers a permanently bonded striping option. Striping consists of a single solid color and a coextruded layer of a single contrasting stripe color. Standard striping pattern is three stripes 120 degrees apart.

SuperGlide® is a coextruded inner layer of low friction media provided standard in all Blue Diamond microduct products. It is also provided as an added option in 1/2" through 2" conduit. The compound of Siloxane and HDPE lowers the already low friction factor of the conduit to below 0.12. This is a significant improvement on the Telcordia Bellcore GRE 3155 Core recommended standard of 0.15.

Blue Diamond HDPE innerduct and conduit has standard identification markers for every run. The duct will be marked with the applicable specification identification, duct size, SDR or SCH rating and sequential footage markers every 2’ as well as date, shift and time of manufacture. Custom identifiers such as a logo or custom print line are also available when allowed by the specifications.

Blue Diamond offers additional options for put ups, pre installed cable, and pull tape. In addition we offer lubrication during the extrusion process for any of our products.

Blue Diamond offers a variety of HDPE accessories to help complete your project requirements. Click here for more information.